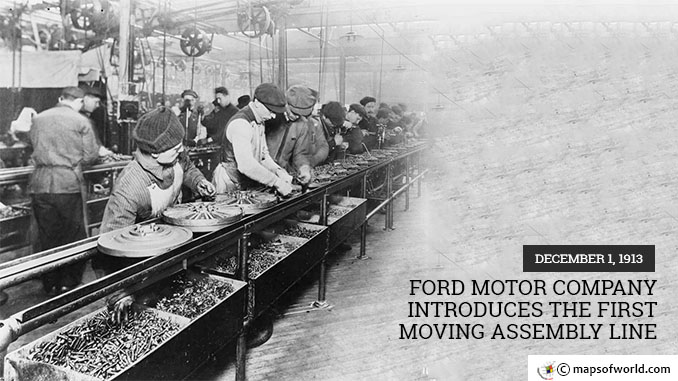

Prior to the 20th century, the manufacturing of cars and other vehicles remained a cumbersome process as each was handcrafted. Automobiles remained exclusive for this reason – far beyond the reach of the common man. This meant that for almost ten years preceding the launch of the Model T by Henry Ford in October 1908, automobiles were available only to the richest Americans and the costs of production were very high. On December 1, 1913, the introduction of the first moving assembly line by the Ford Motor Company revolutionized industrial manufacturing processes, thereby cutting costs and improving efficiency. The moving assembly line marked a turning point in the growth of the industrial era – both in the US and elsewhere in the world. At the time of the launch of the Model T, Henry Ford had cherished a desire to build a car for the masses – an automobile that would be sturdy, easy to drive and maintain , and economical at the same time. “I will build a motor car for the great multitude”, he had said. While Ford’s Model T was designed specifically to serve the requisites of American middle-class, the high cost of producing the model ensured that the cost price hovered about $850 – a price too steep for most Americans. The Ford Motor Company’s endeavor to decrease cost of production by boosting productivity needed a breakthrough that would make Henry Ford’s dream a reality. The moving assembly line not only achieved this objective but also revolutionized industrial processes and transformed industry for all times to come. By late 1913, Henry Ford had most of his engineers and designers working on a smart automation system which culminated in the introduction of the moving assembly line in the company’s Highland Park, Michigan automobile factory. Initially the Ford Motor Company used its new assembly line technique to manufacture flywheel magnetos at the Highland Park factory unit. While the standard practice had been for each worker to assemble his own magneto, the introduction of the assembly line meant that the entire operation was divided into 29 tasks. These now started to be performed by 29 different workmen along a moving belt. The average time required to assemble a magneto dropped from 20 minutes to 13 minutes. With improvisations this came down further to about 5 minutes. Soon the automobile frame – the chassis of Model T – started to be put together using this technique. A motorized belt system using ropes was fashioned to pull the chassis past the factory’s workers as they completed work on it. Workers in the factory would add parts to the chassis on the factory floor. This quick movement system cut down the man-hours required to work on the automobile by more than half. A Model T that initially required over twelve hours to be completed now required only six. Ford’s team further worked on improvisations to the model assembly line and the production time was further cut down to an hour and thirty-three minutes by the following year. Along with the time, the costs of producing the Model T dropped drastically and the boost received by production was tremendous. Model T soon became an affordable automobile and demand rose exponentially. Within the next three years, the cost price of Model T had fallen drastically to about $300 and sales received a massive boost. Between 1913 and 1927, over 15 million Model T cars were built. The moving assembly line ushered in a new era of industrial revolution in the US and across the globe. Critics claim that the credit of introducing the moving assembly line is wrongly claimed by the Ford Motor company since the history of this technique can be traced back to the 19th-century meat-packing industry in Cincinnati, Ohio where it was referred to as a Disassembly Line. In Cincinnati and later in Chicago, overhead trolleys were used to carry meat to various workmen who would work on curing and dressing the meat. Later, Ranson E. Olds had also experimented with the technique in the automobile industry but a weak design had kept the car from becoming a success. At any rate, Henry Ford’s introduction of the moving assembly line was a phenomenal success and allowed for industries across the world to consider mass production seriously for the first time.

December 1 1913 – Ford Motor Company introduces the first moving assembly line

Prior to the 20th century, the manufacturing of cars and other vehicles remained a cumbersome process as each was handcrafted. Automobiles remained exclusive for this reason – far beyond the…